Our company has all the necessary know-how for the management of the while or part of the production process in the manufacturing of rubber rollers, rubber wheels and special details rubber-metal, rubber details ans suction cups.

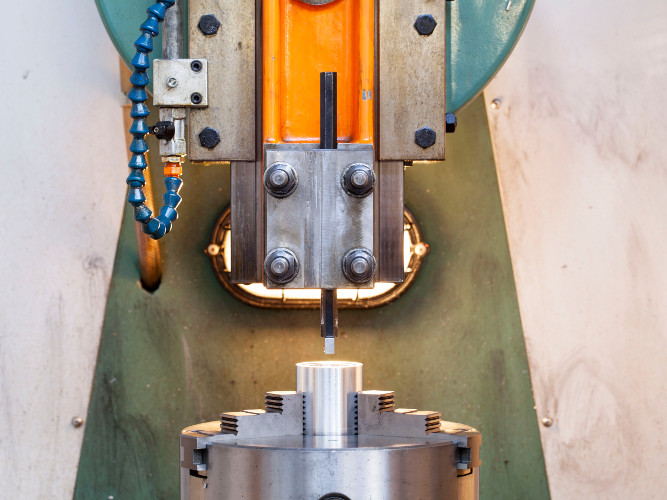

Metal Core Construction

The metal parts are made by controlled numeric machines after a detailed analysis of the customer technical design.

Gumming

Gumming consists of applicating to the metal parts the rubber coating of the roller or the particular parts. This can be made by different techniques:

- Compression molding

- Cold formation molding

- Autoclave

- Strenght mounting

Correction

Generally the correction (grinding) only affects the rubber parts of rollers and wheels. We also rectify the metallic part of the roller, after the gumming, for particular customers needs. (For example precision and concentricity of the roller). Sometimes we also grind the metal shaft after gumming.

Mold Making

In the case of gumming with compression molding or cold molding it is necessary to have a mold which ensure the desire shape. Thanks to our know-how and years of experience, our company is also able to make molds.